We construct conveyor systems for the energy and environmental fields on a global scale.

Based on past results, we construct and offer proposals (flow plans, model selection, operation plans, electrical control systems) for our own original conveyor transportation equipment adapted for a diverse range of transported items, such as belt conveyors, chain conveyors, apron conveyors, screw conveyors, various feeders, and more, and we carry out equipment design as well. Because production occurs primarily at our subcontract factories located overseas, our services can be provided at low cost both domestically and internationally.

We also specialize in products for handling bulk materials.

We provide support from the planning stages for conveyor equipment used for receiving, storage, delivery, weighing, granularity adjustment, and so on. From design to equipment procurement, manufacturing, test operations, and maintenance, we utilize integrated system engineering that harnesses our experience and original technology to respond to a wide range of client needs.

Our Specialties

General boiler auxiliary machinery, including equipment for fuel (coal and biomass) receiving, storage, and supplying, and ash treatment facilities (fly ash and bottom ash).

General incinerator auxiliary equipment, including incineration ash (main ash and fly ash) conveyance equipment for industrial waste material incineration facilities.

General canned product manufacturing, such as hoppers, silos, and assorted mountings, and design and manufacturing of a wide range of electrical equipment.

Target Clients

Major trading companies, major plant manufacturers, power companies, etc.

Main Usage Examples

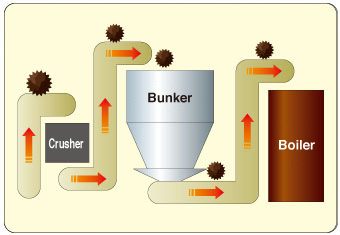

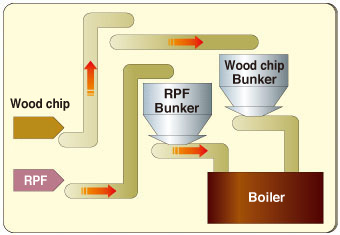

[Biomass (scrap material for wood construction, RPF) conveyance equipment, coal receiving/storage/supplying equipment]

[Primary component examples]

Truck dampers, belt feeders with hoppers, bucket elevators (or steep slope chain conveyors), steel storage tanks, portable feed machines (table feeders), measuring feeders (belt feeders, etc.)

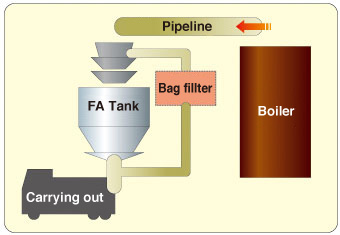

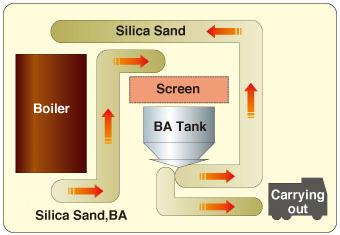

[Ash treatment facilities (bottom ash and fly ash)]

[Primary component examples]

Bottom ash: water seal chain conveyors, water cooling jacket screw feeder, continuous bucket chain conveyors, humidifiers; Fly ash: pneumatic conveyors (various pneumatic conveying equipment, including high-pressure feed/suction/low-pressure feed types)